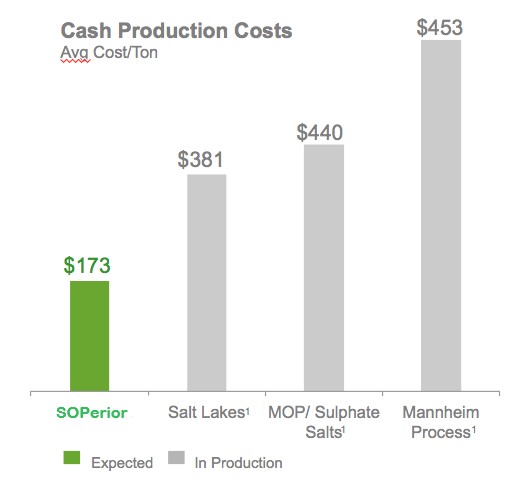

There are two methods used in the production of SOP. Primary production methods include directly extracting SOP from mineral ores containing both potassium and sulphate. This method is currently rare and may yield by-products, which can contribute additional revenue. SOPerior Fertilizer Corp. plans to use this method of production at the Blawn Mountain Project.

The most common secondary production method is referred to as the Mannheim Process and involves the reaction of KCI with sulphuric acid. This method for producing SOP accounts for 50% to 60% of the global. The Mannheim Process is the most expensive method of producing SOP due to energy requirements and high cost of purchasing MOP and sulphuric acid. Secondary production is also possible through the reaction of KCI with sulphate salts.

Cash Cost by Production Method

1 CRU 2013

Process Method and Cost Comparisons

| Region |

Process

Method |

World

Capacity |

Process

Inputs |

Products |

Avg

Cost /

Tonne |

Future

Outlook |

China/

Europe |

Mannheim |

43% |

|

|

$453 |

High cost/

By-Product

limits growth |

| Europe |

MOP and Kieserite |

22% |

|

|

$440 |

No

Additional

Deposits |

China/

USA/

Chile |

Salt Lakes |

35% |

|

- SOP

- Magnesium Chloride

- Sodium Chloride

|

$381 |

No

Additional

Suitable Lakes |